Features

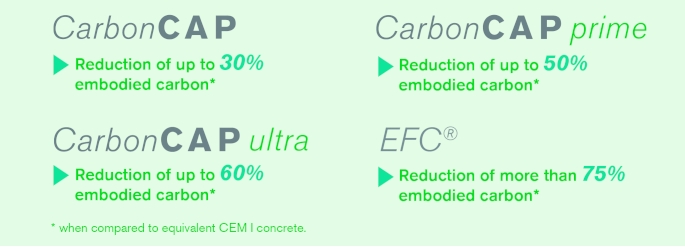

Sustainability - mixes within the CarbonCAP range have lower levels of embodied carbon on account of their use of supplementary cementitious materials in whole or part substitution for Portland Cement

Independently verifed - an Environmental Product Declaration (EPD) is available for all mixes within the range. This details the LCA (Life Cycle Analysis) showing the carbon intensity of each mix to be used in the project, independently verifed by a third party.

CarbonCAP can be delivered by truck and can be placed by chute and pump like traditional concrete.

CarbonCAP is supplied by Capital Concrete from batching plants which are all third party accredited by QSRMC.

To place an order or to talk to us about the requirements for your project please call our team on 020 3974 0520.

Applications

The CarbonCAP range can be utilised in all applications where traditional concrete is used. For example slabs, walls, columns, footings traditional slip form paving including machine paving, deck units and tunnel segments in major infrastructure projects.

All CarbonCAP mixes are designed to ensure there is no compromise on performance, using latest mix design technology to ensure specifcation is met and suitable for end use.

Benefits

High durability

- Low CO2 concrete in comparison to conventional concretes

- Acid and sulphate resistant

- Fire resistant to AS1530 Part 4 2005

- Chloride ion ingress resistant.

Looks great

- Natural off-white colour

- Clean off-form finish

- Compatible with colour pigments and oxides

- Placed by pump or skip.

For more specific technical support please contact one of our team on 020 3974 0520.

Case Studies

Sustainable Concrete For Deep Raft Pour Modebest Wood Wharf G10

The raft slab with a depth of 3.725m has been supplied with 1200m3 of 70% GGBS blend C40, which falls within our CarbonCAP ultra range.

Jack Sindhu, Technical Manager at Capital Concrete, stated: “The concrete mix was developed with a low binder content pumpable mix with low -thermal coefficient aggregate and to achieve a low heat of hydration. The Peak temperature recorded was 51°C with a temperature differential of

21°C."

220 tonnes of CO2 saved using CarbonCAP ultra

Supplies To Skanska Costain Strabag Joint Venture

HS2’s ‘Central Section’ in London is being solely supplied by Capital Concrete. Capital Concrete have already supplied a substantial amount of material to enabling works for the Central Section, including 952m3 of high GGBS blend concrete in a single pour carried out over the busy pre-Christmas period in December 2021, which involved over 100 truck deliveries in a single shift.

Jack Sindhu, Technical Manager at Capital Concrete, explains how the specialist properties of the mix itself can benefit the project: “The use of a high GGBS blend levels in mixes reduces the likelihood of any thermal cracking in the concrete and provides a low embodied carbon and sustainable concrete,” says Jack. “The inclusion of limestone coarse aggregate is also beneficial, for thicker sections cast as it provides a lower thermal conductivity.”

155 tonnes of CO2 saved using CarbonCAP prime

Latest News

Capital Concrete Supplies Record Breaking Earth Friendly Concrete Pour For Permanent Works

Capital Concrete has supplied the largest ever continuous pour of their cement-free Earth Friendly Concrete, to the London Power Tunnels Project.

736m3 of Earth Friendly Concrete (EFC) has been used to fill the base of a 55m deep tunnel drive shaft at the National Grid’s Hurst substation in South London. The pour supplied to contractor Hochtief-Murphy joint venture (HMJV) took place in April and is the first time EFC has been used in large scale permanent construction.

Concrete and screed calculator

Our concrete and screed calculator will help you determine the quantity of concrete or screed you need for your project. Please enter the Width, Length and Depth of the area, then click on the Calculate button.

Where to find us

Head Office

Eclipse House, Eclipse Park, Sittingbourne Road, Maidstone, Kent ME14 3EN

t: 020 3974 0520

Click here to view or download the map of our site locations.

Wembley

Capacity: 300m3/hr, wet

Neasden Rail Siding,

The Rail Yard, Drury Way,

Neasden NW10 0JJ

t: 020 8016 6764

Covering all areas within an hour’s journey from our plant including: Wembley and Cricklewood, Finchley, Golders Green, Kilburn, Muswell Hill, Islington, Edgeware, Harrow, Old Oak Common, Acton and Paddington.

Bow

Capacity: 60m3/hr, dry

Chapman Road, Bow,

London E9 5DW

t: 020 8986 6616

Covering all areas within an hour’s journey from our plant including: Enfield, Stratford, Woolwich, Holloway, Canary Wharf and Clerkenwell.

Cricklewood

Capacity: 160m3/hr, wet

Cricklewood Railway Yard, 400 Edgware Road, Cricklewood

NW2 6ND

t: 020 8187 1560

Covering areas including: Wembley and Cricklewood, Finchley, Golders Green, Kilburn, Muswell Hill, Islington, Edgeware, Harrow, Old Oak Common, Acton and Paddington.

Croydon

Capacity: 70m3/hr, wet/dry

Endeavour Way,

Beddington Farm Road,

Croydon, Surrey CR0 4TR

t: 020 8665 6348

Covering all areas within an hour’s journey from our plant including: Orpington, Bromley, Caterham, Epsom, Sutton and Wimbledon.

Enfield

Capacity: 50m3/hr, dry

Jeffreys Road, Enfield EN3 7UA

t: 020 8805 8150

Covering all areas within an hour’s journey from our plant including: Cheshunt, Waltham Abbey, Enfield, Potters Bar, Palmers Green, Waltham Forest and Hoddesdon.

Langley

Capacity: 60m3/hr, wet

Langley Station Road, Langley SL3 6ED

t: 01753 291935

Covering all areas within an hour’s journey from our plant including: Langley, Feltham, Staines, Kingston, Richmond, Brentford, Hayes, Heathrow, Slough, Maidenhead, Bracknell, Woking and Cobham.

Rainham

Capacity: 80m3/hr, wet

Launders Lane, Rainham,

Essex RM13 9GJ

t: 01708 206839

Covering all areas within an hour’s journey from our plant including: Dagenham, Barking, Grays, Tilbury and Upminster.

Romford

Capacity: 60m3/hr, wet/dry

Hainault Road, Little Heath,

Romford, Essex RM6 5SS

t: 020 8599 3929

Covering all areas within an hour’s journey from our plant including: Loughton, Enfield, Epping, Brentwood, Barking and Dagenham.

Silvertown

Capacity: 200m3/hr, wet

Peruvian Wharf, North Woolwich

Road, Silvertown E16 2AB

t: 020 3926 7551

Covering all areas within an hour’s journey from our plant including: Stratford, Woolwich, Holloway, Canary Wharf, Barking, London Bridge and Greenwich.

Staines

Capacity: 100m3/hr, wet

Ashford Road, Laleham

Middlesex TW18 1QF

t: 01784 770270

Covering all areas within an hour’s journey from our plant including: Feltham, Staines, Kingston, Richmond, Brentford, Hayes, Heathrow, Slough, Maidenhead, Bracknell, Woking and Cobham.

Wembley

Capacity: 300m3/hr, wet

Neasden Rail Siding,

The Rail Yard, Drury Way,

Neasden NW10 0JJ

t: 020 8016 6764

Covering all areas within an hour’s journey from our plant including: Wembley and Cricklewood, Finchley, Golders Green, Kilburn, Muswell Hill, Islington, Edgeware, Harrow, Old Oak Common, Acton and Paddington.